Turnkey Solution of CBD & THC (Herbal Oil Cannabis Oil) Distillation

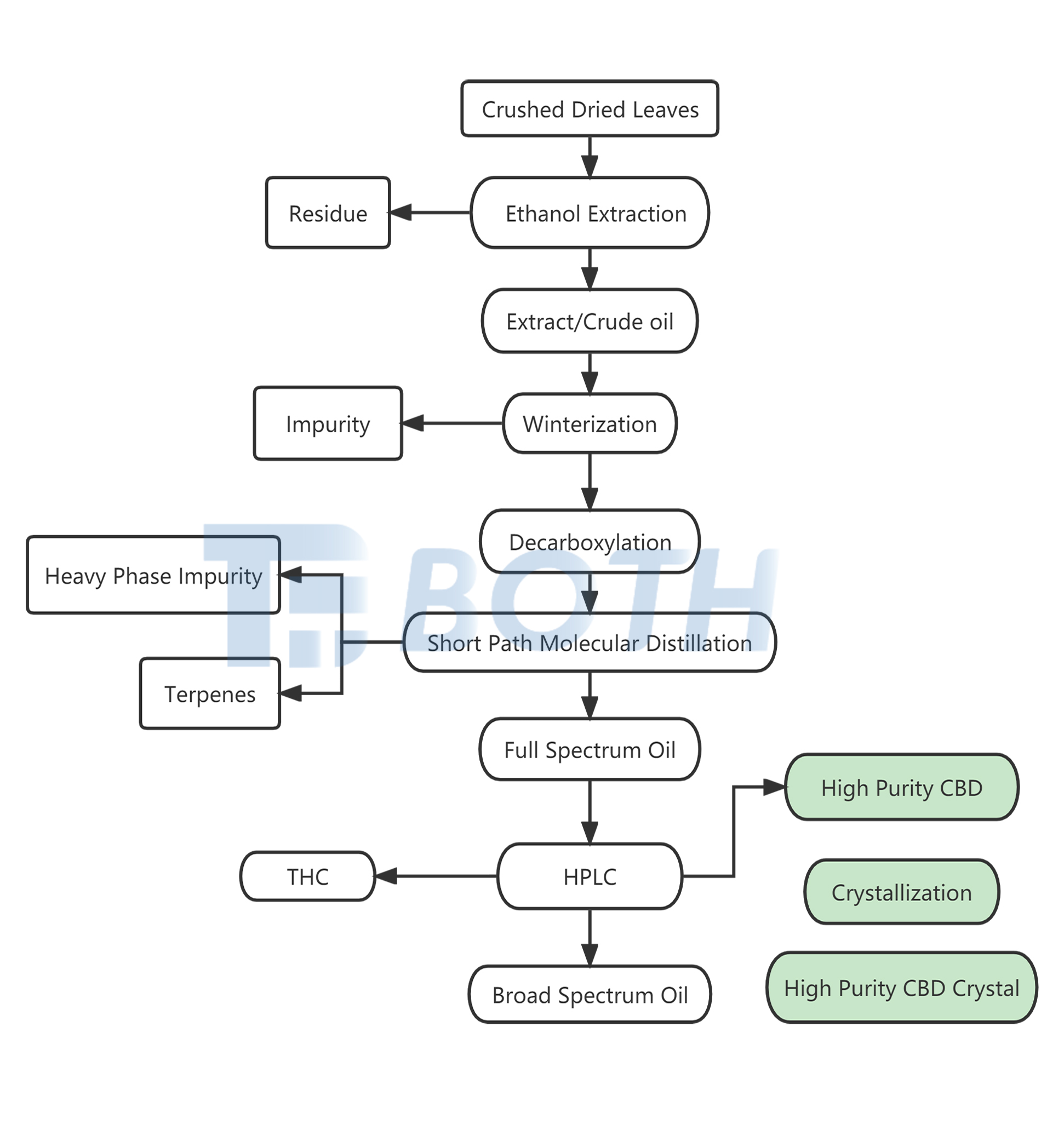

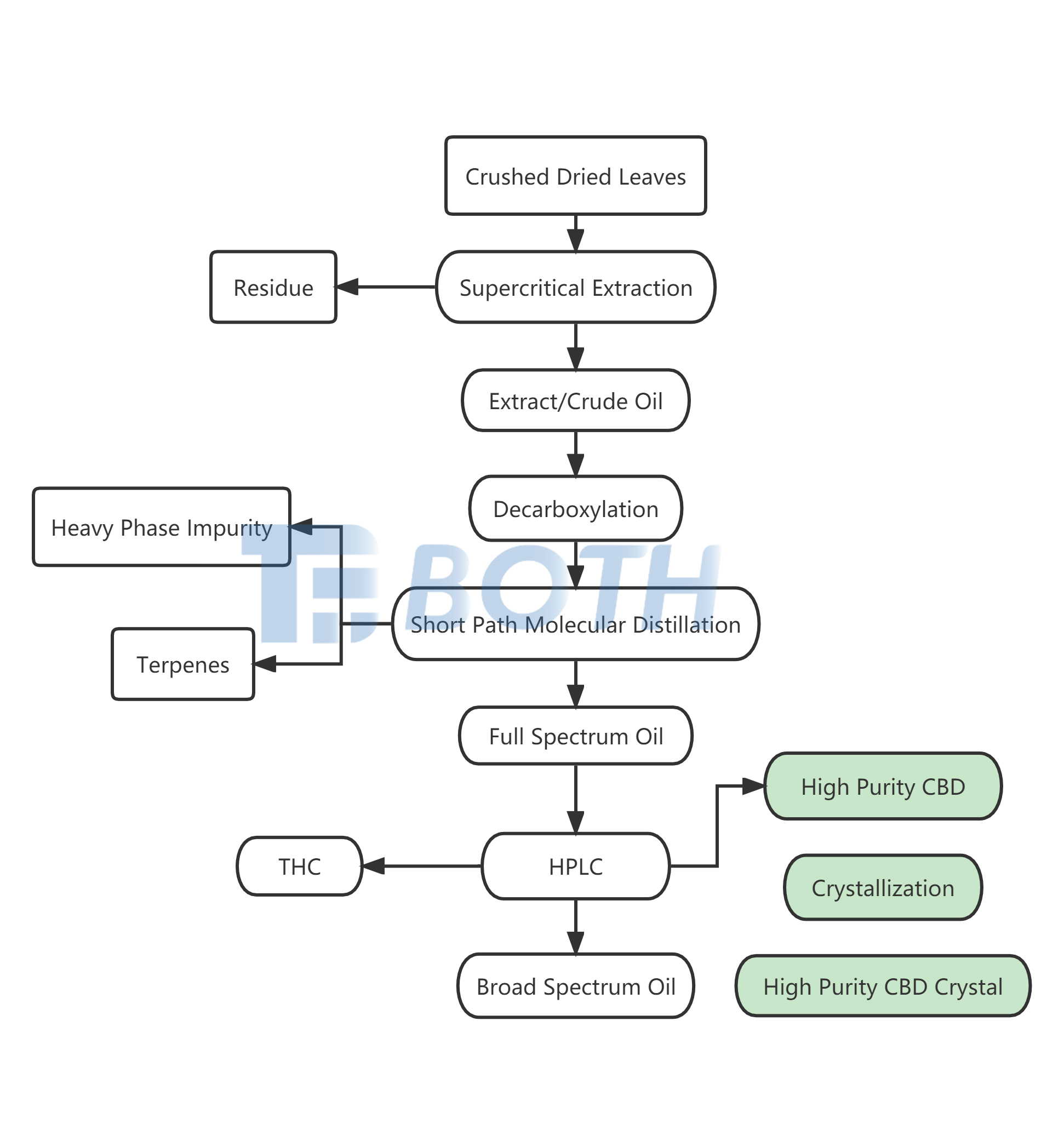

● Dried and crushed herbal flowers and leaves

● Extract by ethanol extraction or supercritical extraction

● Freezing, decarboxylation and other pretreatment

● Molecular distillation separation and purification

● Chromatography to remove herbal or further purify herbal

● Crystallization to obtain high purity herbal

Ethanol Extraction Method

Supercritical Extraction Method

| Comparison Items | BOTH Unique Extraction Technology | Traditional Cryo Ethanol Extraction Method |

| Extraction Temp. | @-20°C~RT | @-80°C~-60°C |

| Energy Consumption | Reduce↓40% | High |

| Production Cost | Decrease ↓20% | High |

| Extraction Efficiency | Around 85% | Around 60%~70% |

| Increase ↑15% | ||

| Extraction Equipment | 2 Sets of Centrifuge Extractors (Usually with higher efficiency) | Traditional Soaking Reactors |

| Countercurrent Extraction method with high efficiency | Low Efficiency | |

| 99% Crude Oil Extraction Rate after the Countercurrent Extraction | A large amount of crude oil remains in the wet biomass | |

| Crude Oil Purify Process | Including Degumming, Chlorophyll, Proteins, Sugars, Phospholipids removing process | Only wax removing but not completed |

| No need to clean and maintain the short path distillation machine Frequently. | Easy to Coke and cause the blocking in the distillation process, even scrap the short path distillation machine. | |

| Herbal Remediation | Destroy Herbal to 0.2% according different requirement | HPLC Only (High Performance Liquid Chromatograph) |

| Adopt HPLC (High Performance Liquid Chromatograph) or SMB if request the Herbal lower than 0.2% | ||

| Solvent Regeneration | Rectification Column to regenerate the Ethanol when purity less than 85% | Abandon/Waste |

Write your message here and send it to us