Traditional Vacuum Freeze Dryer

● Optional with pre-freezing function, no external pre-freezing storage, to solve the mobile liquefaction of materials and pollution risk;

● The freeze-dried chamber and shelves are made in strict accordance with GMP requirements. The chamber is made of SUS304 grade stainless steel, and the internal is mirror polished.

● The chamber adopts cold trap integrated design, compact structure, easy to clean, no sanitary dead Angle, and has an observation sight window;

● Cold trap that water catcher using sanitary grade stainless steel SUS304 processing, condensation area is greater than similar products 50%, can shorten the freeze drying time, reduce production costs;

● Shelves can be customized according to customer requirements of D31(6363) aluminum alloy material for anodizing treatment or SUS304 stainless steel shelves;

● The refrigeration system are mainly imported brands, with strong refrigeration, fast cooling, stable and reliable performance;

● According to the material and customer needs to provide a variety of vacuum pump units;

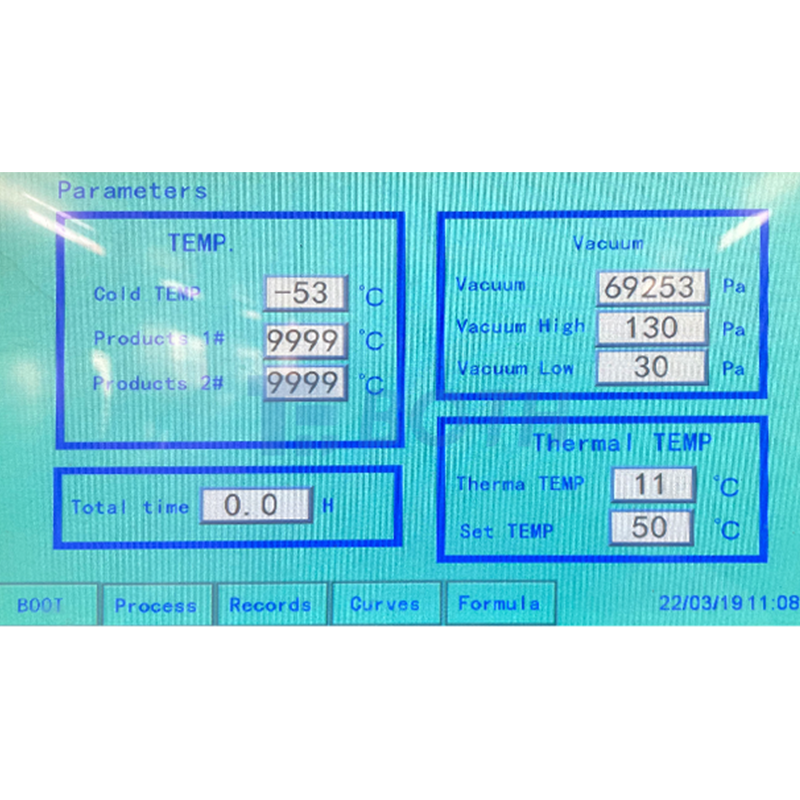

● PLC control system adopts Siemens PLC automatic control, simple operation, according to the production process needs to arbitrarily switch control mode and parameter settings, to meet the requirements of different materials freeze-drying process;

● 7-inch real color touch LCD screen, real-time recording display cold trap, material, shelves temperature and vacuum degree, generate drying curve;

SUS304 Stainless Steel Main Body

The main body is made of sanitary stainless steel SUS304 stainless steel, in line with GMP standards.

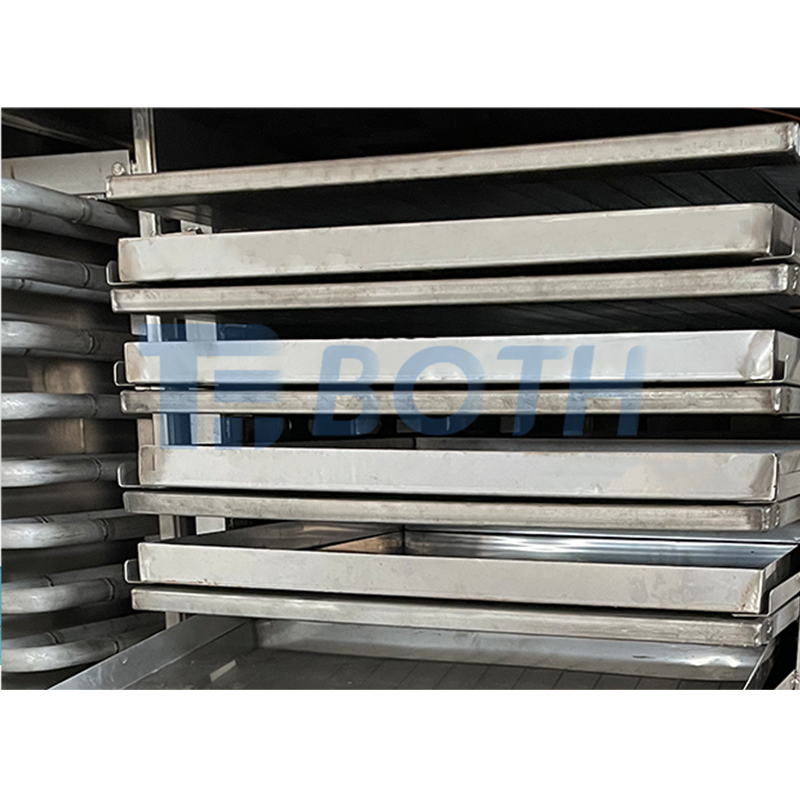

Shelves

Shelves can be customized according to customer requirements of D31(6363) aluminum alloy material for anodizing treatment or SUS304 stainless steel shelves, smooth surface uniform heat conduction effect.

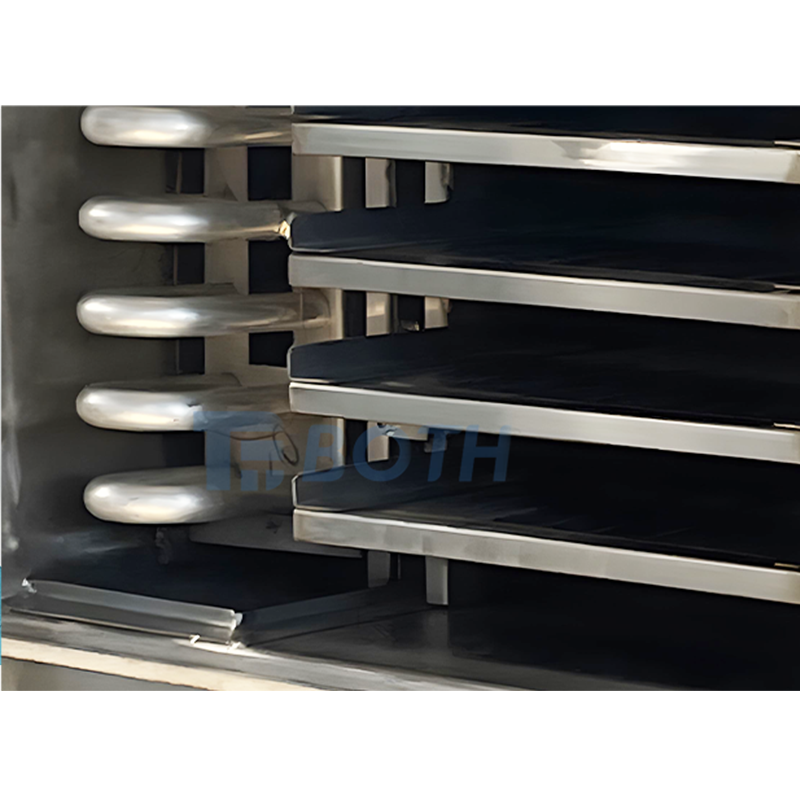

Cold Trap

Cold trap that Water Catcher using sanitary grade stainless steel SUS304 processing, condensation area is greater than similar products 50%, can shorten the freeze drying time, reduce production costs;

PLC Control System

PLC control system adopts Siemens PLC automatic control, simple operation, according to the production process needs to arbitrarily switch control mode and parameter Settings, Taiwan WEINVIEW touch screen, simple operation.

International Famous Brand

World Brand Compressor Unit: Italy FRASCOLD, Germany BITZER, USA EMERSON COPELAND, Italy DORIN, France TECUMSEH, Brazil EMBRAC,Etc.with high refrigeration efficiency and stable performance.

BTFD-1(1m2)

BTFD-5(5m2)

BTFD-20(20m2)

BTFD-100(100m2)

| Model | BTFD-1 | BTFD-5 | BTFD-10 | BTFD-20 | BTFD-50 | BTFD-100 |

| Shelves Efficient Drying Area | 1 ㎡ | 5 ㎡ | 10 ㎡ | 20 ㎡ | 50 ㎡ | 100 ㎡ |

| Process Capacity /Bath (Raw Material) | 12kg/batch | 60kg/batch | 120kg/batch | 240kg/batch | 600kg/batch | 1200kg/batch |

| Power Supply | 380V/50Hz or Customized | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Installed Power | 6kw | 16kw | 24kw | 39kw | 125kw | 128kw |

| Average Power Consumption | 3 kilowatt hour | 6 kilowatt hour | 12 kilowatt hour | 22 kilowatt hour | 70 kilowatt hour | 75 kilowatt hour (need own boiler) |

| Dimensions (L*W*H) | 2000*1000*1500mm | 3000*1400*1700mm | 3800*1400*1850mm | 4100*1700*1950mm | 6500* 2100*2100mm (cylinder-shaped) | 10600*2560*2560mm (cylinder-shaped) |

| Weight | 800kg | 1500kg | 3000kg | 40000kg | 15000kg | 30000kg |

| Matrial Trays | 645*395*35mm | 600*580*35mm | 660*580*35mm | 750*875*35mm | 610*538*35mm | 610*610*35mm |

| Trays No. | 4 Pcs | 14 Pcs | 26 Pcs | 30 Pcs | 156 Pcs | 306 Pcs |

| Cold trap/Water Catcher Temp. | ≤-45℃ | |||||

| Shelves Temp. | RT-95℃ | RT-95℃ | RT-95℃ | RT-95℃ | RT-95℃ | RT-95℃ |

| Vacuum Degree | ≤10pa | ≤10pa | ≤10pa | ≤10pa | ≤60pa | ≤60pa |

| Main Body Material | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 |

| Compressor | Germany BITZER | Germany BITZER | Italy FRASCOLD | Italy FRASCOLD | Taiwan Fusheng | Taiwan Fusheng |

| Compressor Power | 2P | 8P | 10P | 10P*2 Sets | 50KW | 75KW |

| Thermal Circulating Fluid | Heat Conducting Silicone Oil /Purified Water | |||||

| Control Mode | PLC Manual /PLC Automatic | |||||

| Control Electrical Accessories | CHINT/Siemens | |||||

| Touch Screen | Taiwan WEINVIEW | |||||

| Remark: | 1-20m² is Square Integrated Vacuum Freeze Dryer (Vacuum, Refrigeration System & Drying chamber Integrated), 50-200m² is Round Split Vacuum Freeze Dryer.(Vacuum, Refrigeration System Separate from Drying Chamber) | |||||