Stainless Steel High Temperature And High Pressure Reactor

Safety

● seal mode: soft seal or hard seal structure

● overtemperature, timeout, overpressure automatic alarm and stop heating, double safety design

● overpressure automatic pressure relief explosion-proof device

Accurate

● Imported from the United States "Smart PID algorithm "temperature control system, double temperature control, interlocking control, eliminate the impact temperature

● using rare earth material strong magnet, dc brushless motor, no noise, long service life, speed/direction free setting

● fast thermal conductivity embedded heating module

Convenient

Data of temperature, speed, torque, time and pressure are automatically saved and EXCEL tables and curves are generated, which are imported to USB disk through USB interface. The device can be monitored and operated on PC or mobile phone through network cables.

Stability

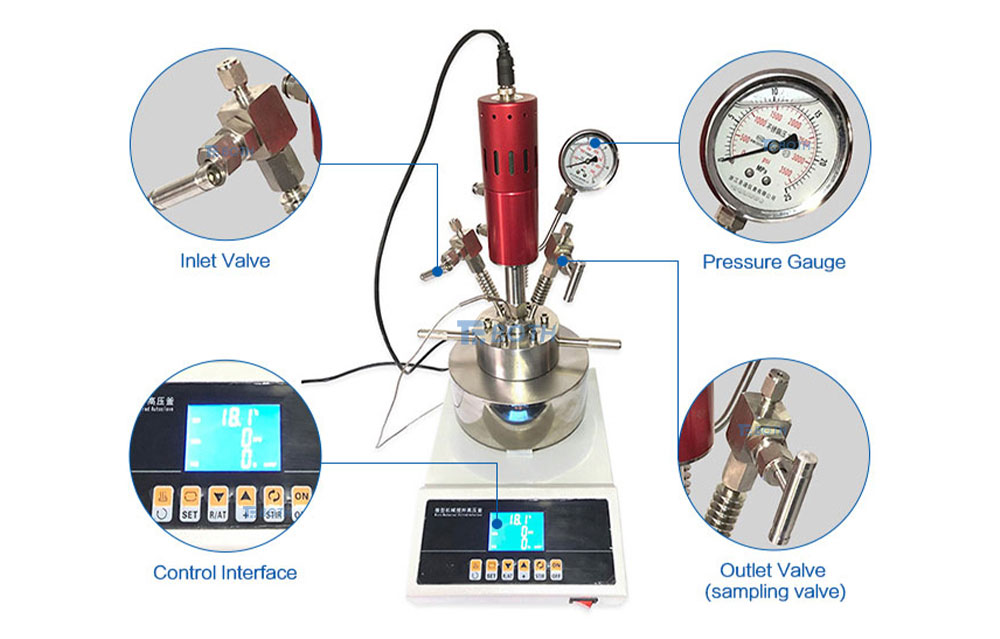

● Valve spinner sealed with alloy surface

● High temperature and corrosion resistance

● radiator device to increase valve life

● Inlet and outlet interface double clamp 1/8 - 1/4

Safety

● Choose High Quality Rod Wool Ring Red Furnace Forging Multiple Complex Integrated Processing

● Sealing Mode: Soft Seal or Hard Seal Structure

● Automatic Alarm and Stop Heating Over Temperature or Timeout

● Automatic Pressure Relief Explosion-proof Device

Precision

● Double Temperature Control, Chain Control, Eliminate The Impact Temperature

● Use Rare Earth Material Strong Magnet, Brushless DC Motor, Noiseless, Long Service Life, Free Setting of Speed/Direction

● Fast Thermal Conductivity Embedded Heating Module

High Efficiency

● Tank Body and Heating Device Can be Separated

● Caliper Interlock Quick Open Structure

Stable

● Valve Spool is Sealed with Alloy Surface

● High Temperature and Corrosion Resistance

● Heat Dissipation Device Increases Valve Life

● Access Interface Double Clamp 1/8 - 1/4

H -LCD Display,Key Operation

H-KJ Design(Quick-open type Mechanical stirring)

H-KC Design(Quick-open type Magnetic stirring)

H-FC Design(Flange formMagnetic stirring)

Z -Touch Screen Operation

Z-KC Design(Quick-open type Magnetic stirring)

Z-KJ Design(Quick-open type Mechanical stirring)

Z-FC Design(Flange form Magnetic stirring)

| Model |

Z-KC |

H-KJ |

| Volume |

25-1000ML |

50-1000ML |

| Kettle Body Material |

304, 316L, 310S, 904L, Hastelloy alloy, titanium, etc |

304, 316L, 310S, 904L, Hastelloy alloy, titanium, etc |

| Sealing Style |

Hard/soft sealing |

/ |

| Kettle Body Structure |

Quick-open type |

/ |

| Liner |

Ptfe/quartz /316L/ Hastelloy/titanium/Monel etc |

PTFE/quartz /PPL |

| Temperature |

0-350℃ |

0-600℃ |

| Thermocouple |

K type |

K type/316L/φ2.0 |

| Pressure |

0-25MPA |

-0.1-25MPA |

| Explosion-proof Pressure |

7-26MPA |

|

| Explosion-proof Device |

Hastelloy alloy material |

Hastelloy explosion-proof film |

| Stirring |

Internal Magneton Stirring |

Shaft-driven blade stirring (torque up to 40KG) |

| Stirring Speed |

0-1500RPM |

0-1000RPM |

| Control Cabinet, Heating Furnace |

One-piece construction |

/ |

| Heating Power |

500-5500W |

500-2500W |

| Heating Equipment |

|

|

| Heating Method |

Electrical Heating |

Module Heating |

| Operation Interface |

7 Inch true color touch screen display |

LCD display, key operation |

| Control System |

USA Imported PID intelligent dual temperature control system, temperature control program, main control kettle temperature, auxiliary control furnace temperature |

PID intelligent double temperature control, effectively prevent impact temperature, temperature control program (optional) |

| Zones of Temperature Control |

Intelligent selection of temperature control for four groups of temperature zones (temperature range can be set independently) |

/ |

| Power Adjustable |

Four groups of zone temperature and power adjustable |

/ |

| Temperature Display |

0.1℃ |

/ |

| Temperature Control Accuracy |

±1℃ (no strong exothermic/endothermic/temperature measuring tube without tetrafluoride Coating) |

±1℃ |

| Temperature Setting |

Double self-setting function, kettle temperature and furnace temperature PID self-setting temperature function |

/ |

| Safety Interlocking |

Overtemperature/overpressure/timeout alarm, stop working, cut off heating |

/ |

| Timing Function |

Insulation timing and start-up timing |

/ |

| Torque Display |

Magnetically coupled torque display |

/ |

| Data Copy |

Furnace temperature, temperature in the kettle, pressure, speed, torque and time can be exported through USB interface data or cut graph |

/ |

| Remote Control |

Through network cable interconnection, it can be operated on a computer, or connected to a LAN mobile phone for remote control (remote monitoring needs to open a cloud server by itself, and the seller provides technical support) |

/ |

| Inlet Valve |

316L stainless steel needle valve, interface size φ3/φ6 |

/ |

| Gas Outlet Valve (Sampling Valve) |

316L stainless steel needle valve, interface size φ3/φ6 |

/ |

| Spanner |

Special dismantling tool |

/ |

| Power Supply |

220V/110V |

|

| Option |

PTFE Cover Reactor Lid , temperature tube, stirring rod and stirring blade, PTFE liquid sample tube, support, screen, etc.; External condensation reflux, etc |

|