Pilot Scale Jacketed Nustsche Filtration Glass Reactor

“#” Type Struction Frame | Fixed Reactor Lid & Main Body (GFR)

● “ #” Type Struction Frame, maintain the overall stability of the equipment.

● No Dead Space PTFE Inclined Discharging Port, through the PTFE hose quick connection receiving flask.

● The Receiving Flask and the Filtration Reactor are designed independently, saving more operation space.

● Oil Drain Manifold Kit simply drain the circulator fluid without splashing and reduce the stress on reactor glassware.

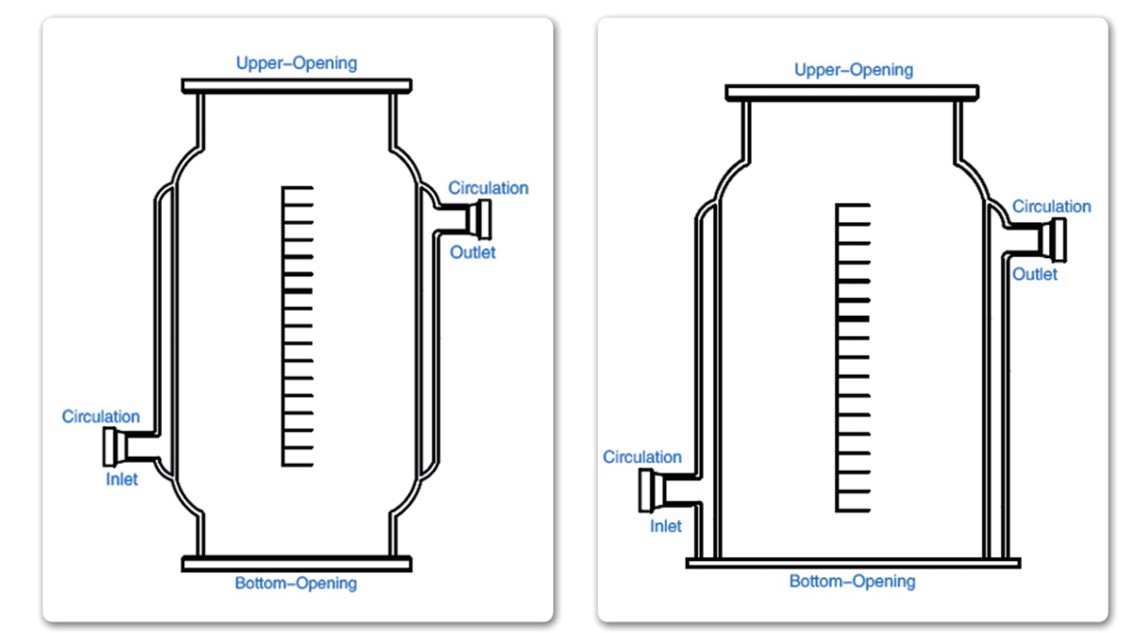

● Circulation Ports are tangential which avoid local overheating, especially near the circulation ports. Ring Baffles inside of thermal layer improve the rapid thermal transitions and uniform temperature distribution. (Optional for 10-50L).

● Full Jacket Design, thermal jacket fully covers the process vessel which offers maximized thermal transfer to the process. (Optional for 10-30L).

“H” Type Struction Frame Reactor |Main Body Can Be Lifted & Tilting Rotation (Vertical Rotation) (GFR-T)

● "H" Type Structure Frame, not only maintain stability, but also greatly save space.

● "H" Type Struction Frame Reactor, the main body can be lifted with 400mm & Tilting Rotation 180° (Vertical Rotation); Convenient for discharging of high viscosity materials, crystal, solid materials and cleaning

“H” Type Struction Frame | Reactor Lid Can Be Lifted | Main Body Can Be Tilting Rotation (Vertical Rotation)(GFR-LT)

Reactor Lid can be lifted automatically, without moving the motor, stirring paddle and other parts rising into the main body, the Reactor Main Body can be rotated with 180°.

| Model | Reactor Height | Lid Lifted | After Lifted |

| GFR-10LT | 1205 | 840 | 2045 |

| GFR-20LT | 1515 | 900 | 2415 |

| GFR-30LT | 1755 | 950 | 2705 |

| GFR-50LT | 2390 | 1080 | 3470 |

Full Jacket Design

Full Jacket Design, thermal jacket fully covers the process vessel which offers maximized thermal transfer to the process.(Optional for 10-50L)

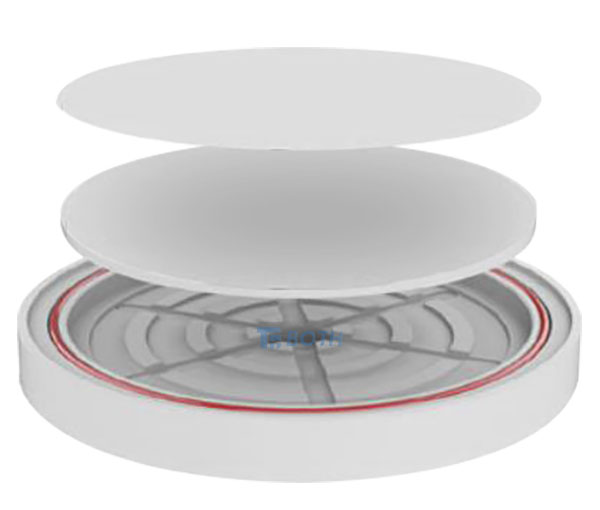

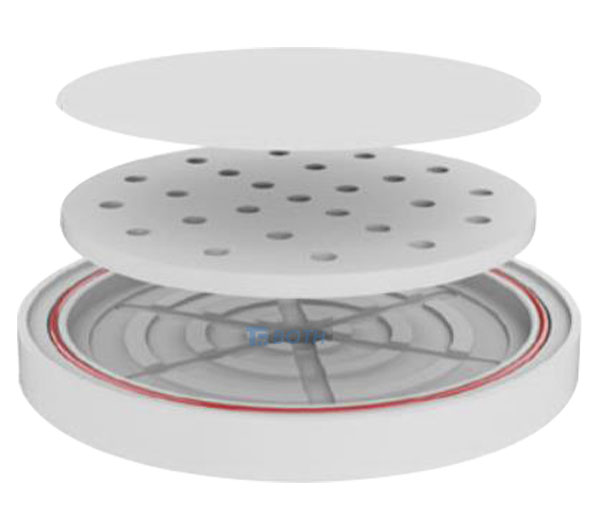

PTFE Filtration Module

● PTFE Coated O-Ring

● PTFE Gaskets with external screw thread

● PTFE Flat Gaskets

● PTFE membrane / fabric (not included by default)

● Glass Disc or PTFE board with holes

● PTFE baseboard with internal screw thread

● PTFE & Glass Discharge Valve

● Lifting/Movement Trolley

● PTFE Tubes

● Glass Receiving Flask

Glass Disc

PTFE board with holes

Hydraulic Lifting/Movement Trolley for easy Filtering Module Installation or Disassembling. (Optional)

Stirring Motor

DC Brushless Motor | AC Induction Motor with Gear Reducer | EX DIIBT4 Explosion Proof Motor | Air Motor

Mixing Sealing Kits

PTFE + Ceramic Bearing Sealing | Ceramic Double Bearing, No Wear Debris | Perfect Stability without Swing in High Speed Stirring.

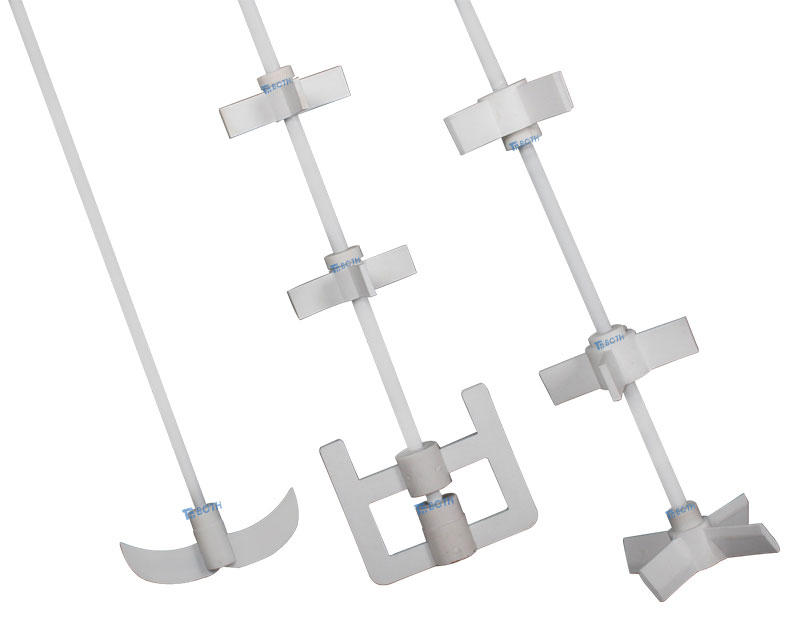

PTFE Stirring Rod

Unibody SUS304 Coated by PTFE Stirring Rod and Impeller No Pollution | Multiple Selections for Impellers PTFE Anchor Type, Pitched Paddle Type, Frame Type.

Reactor Main Body

Single/Dual/Triple Layers |Stainless Steel Hybrid | Spherical | Cylinder

Insulation Connection Hose

Protect the Reactor Vessel | Reduce The Stress on Reactor Vessel | Simply Draining of the Circulator Fluid without Splashing

Discharging Valve

Patented Design, No Slip, No Leakage | Zero Dead Space | The Inclined Discharge Port expanded to 35mm

| Model* |

GFR-10 |

GFR-20 |

GFR-30 |

GFR-50 |

GFR-100 |

GFR-150 |

GFR-200 |

| ①Optional |

GFR-10T |

GFR-20T |

GFR-30T |

GFR-50T |

‒ |

‒ |

‒ |

|

GFR-10LT |

GFR-20LT |

GFR-30LT |

GFR-50LT |

‒ |

‒ |

‒ |

|

| Glass Material |

High Borosilicate Glass 3.3 |

||||||

| Frame Structure |

"#" or “H” Type Structure Frame |

"#" Type Structure Frame |

|||||

| Wetted Parts |

Glass and PTFE without Any Metal Pollution |

||||||

| Reactor Capacity |

10L |

20L |

30L |

50L |

100L |

150L |

200L |

| Jacket Type* |

Sooth Wall inside of Thermal Jacket |

||||||

| ②Optional |

Ring Baffles inside of Thermal Jacket |

‒ |

|||||

|

Full-Jacket Design |

Non-Full-Jacket Design |

||||||

| Thermal Jacket Volume |

3L |

6L |

9L |

15L |

30L |

45L |

60L |

| Filtration Area |

363 cm² |

615 cm² |

615 cm² (1256 cm² Customized) |

||||

| Filtration Micron |

Micron: 0.2μm to 200μm |

||||||

| Stirring Motor* |

AC Induction Motor with Gear Reducer |

||||||

|

120W |

120W |

120W |

250W |

250W |

400W |

400W |

|

|

50 ~ 600 RPM |

|||||||

| ③Optional |

Ex DIIBT4 Explosion Proof Motor |

||||||

|

180W |

180W |

180W |

250W |

370W |

750W |

750W |

|

|

50 ~ 600 RPM |

|||||||

| Integrated Control & Display |

Current Stirring Speed/Materials Temperature |

||||||

| Stirring Rod |

Unibody SUS304 Coated by PTFE Stirring Rod and Impeller |

||||||

| Stirring Impeller |

PTFE Anchor Type, Pitched Paddle Type, Frame Type |

||||||

| Sealing for Agitator |

PTFE + Ceramic Bearing Double Sealing |

||||||

| Glass Lid* |

265# |

340# |

340# (465# Customized) |

||||

| 7 Openings: ● Dropping Feeding Funnel: 40/40 ● Solid Materials Feeding: 95# Flange Neck ● Stirrer: 60# Flange Neck ● Liquid-Feeding: DN25 ● Temperature Probe: DN25 ● Condenser Reflux: S50/20 ● Pressure Release/Vacuum Port/Gas-inlet: 34/34 or /Spray Cleaning: DN25 or PH measurement: 50# Flange Neck or Customized Ultrasonic Neck |

|||||||

| ④Optional |

‒ |

8 Openings: ● Dropping Feeding Funnel: 40/40 ● Solid Materials Feeding: 95# Flange Neck ● Stirrer: 60# Flange Neck ●Liquid-Feeding DN25 ● Temperature Probe: DN25 ● Condenser Reflux: S50/20 ● Pressure Release/Vacuum Port/Gas-inlet: 34/34 ● Spray Cleaning: DN25 or PH measurement: 50# Flange Neck or Ultrasonic Neck |

|||||

| Constant Pressure Drop Feeding Funnel* |

Single Layer Dropping Feeding Funnel with PTFE Needle Valve and Equalizing Arm |

||||||

|

2000 ml |

|||||||

| ⑤Optional |

1) Jacketed Glass Feeding Funnel 2) Powder Feeding Funnel 3) Peristaltic Pump or Other Metering Pumps Feeding |

||||||

| Temperature Probe |

PT100 with PTFE Layer +/-1°C |

||||||

| Condenser |

Double Cooling Coil Condenser |

||||||

| Cooling Area |

0.4 M² |

0.4 M² |

0.4 M² |

0.4 M² |

0.9 M² |

1.5 M² |

1.5 M² |

| Operating Temperature |

.-90°C to +230°C |

||||||

| ΔT - Thermal Shock Resistance |

90°C (Double Wall), 60 °C(Triple Wall) |

||||||

| Operating Pressure |

Full Vacuum to Atmospheric Pressure |

||||||

| Operating Jacket Pressure |

Up to +0.5 bar (0.05 MPa) |

||||||

| Power Supply |

220~240V, 50Hz/60Hz or Customized |

||||||

| Remark | ①GFR-10/50T, Reactor Main Body can Be Lifted & Tilting Rotation (Vertical Rotation 180°); GFR-10/50LT, Reactor Lid Can be Lifted (Dump Materials or Clean Reactor without Moving Motor, Stirring Paddle and Separate Probe);Main Body Can Be Tilting Rotation (Vertical Rotation 180°) ②Ring Baffles inside of Thermal Jacket is an Optional Choice for 10~50L Reactor; Especially for High Precision Temperature Control Process; Full-Jacket Design is Only Available for 10~30L Reactor. ③Stirring Motor, Explosion Proof Motor is An Option for Upgrading. For High Viscous Materials, Can Be Upgraded to 550W 750W and 1500W High-Power Motors. ④8 Openings is Customized Optional for 30~200L. ⑤Constant Pressure Drop Feeding Funnel can be replaced with: ● Jacketed Glass Feeding Funnel; ● Powder Feeding Funnel; ● Peristaltic Pump or Other Metering Pumps Feeding |

||||||