The storage of ginseng is a challenge for many consumers because it contains a significant amount of sugar, which makes it prone to moisture absorption, mold growth, and insect infestation, thus affecting its medicinal value. Among the processing methods for ginseng, the traditional drying process often results in a loss of medicinal efficacy and a poor appearance. In contrast, ginseng processed with a vacuum freeze-dryer can preserve its active ingredients, including volatile components like ginsenosides, without loss. The products processed this way, often referred to as “active ginseng,” have a higher concentration of active compounds. "BOTH" Freeze Drying, as a professional vacuum freeze-drying service provider, has conducted in-depth research on the freeze-drying process for ginseng and aims to help researchers carry out freeze-drying operations more effectively.

1. How to Set the Eutectic Point and Thermal Conductivity of Ginseng

Before starting the freeze-drying process, it is essential to determine the eutectic point and thermal conductivity of ginseng, as these factors will influence the freeze-dryer’s parameter settings. Based on the Arrhenius (S.A. Arrhenius) ionization theory and experiments by various scientists, the eutectic point temperature for ginseng is found to be between -10°C and -15°C. Thermal conductivity is a crucial parameter for calculating cooling consumption, heating power, and drying time. Since ginseng has a honeycomb-like porous structure, it can be treated as a porous material, and the steady-state heat conduction method can be used to measure its thermal conductivity. In a freeze-drying study conducted by Professor Xu Chenghai at Northeastern University, it was found that the thermal conductivity of ginseng is 0.041 W/(m·K) using the heat flux calculation formula and testing operations.

2. Key Points in the Ginseng Freeze-Drying Process

"BOTH" Freeze Drying summarizes the ginseng freeze-drying process into pre-treatment, pre-freezing, sublimation drying, desorption drying, and post-treatment. This process is similar to that of many other herbs. However, there are many details to pay attention to. Four-ring Freeze Drying recommends cleaning the ginseng before freeze-drying, shaping it properly, and selecting ginseng roots with similar diameters. Place silver needles on the surface of the ginseng during processing. This preparation can help achieve more thorough drying, reduce drying time, and result in more aesthetically pleasing freeze-dried ginseng.

Appropriate Temperature During Pre-Freezing

In the pre-freezing phase, the ginseng’s eutectic point temperature is around -15°C. The freeze-dryer’s shelf temperature should be controlled at around 0°C to -25°C. If the temperature is too high, the surface of the ginseng may develop bubbles, shrink, and other issues that affect the experiment’s results. The pre-freezing time depends on the ginseng’s diameter and the performance of the freeze-dryer. If an appropriate freeze-dryer is used, lowering the ginseng from room temperature to around -20°C and setting the pre-freezing time to 3-4 hours will yield the best results.

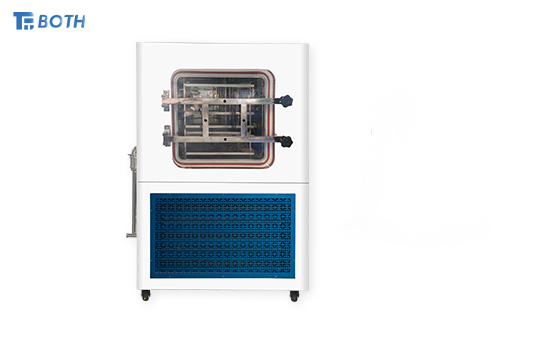

"BOTH" Freeze Drying offers a range of experimental freeze-dryers that can help researchers achieve excellent pre-freezing results. For example, the "BOTH" PFD-50 freeze-dryer has a minimum temperature of -75°C, and its shelf cooling rate can drop from 20°C to -40°C in under 60 minutes. The cold trap cooling rate can drop from 20°C to -40°C in under 20 minutes. The shelf temperature range is between -50°C and +70°C, with a water collection capacity of 8KG.

How to Operate During Sublimation Drying to Avoid Failure

Sublimation drying of ginseng is a complex process that requires continuous heat supply to the sublimation latent heat while ensuring that the sublimation interface temperature remains below the eutectic point. During this process, special attention must be paid to maintaining the temperature of the freeze-dried ginseng at or below the collapse temperature, which is considered to be around -50°C. If the temperature is too high, the product will melt and be wasted. To ensure smooth drying, precise control of heat input and ginseng temperature is necessary to avoid experiment failure. Time is also a key factor, and research suggests that setting the sublimation drying time between 20 to 22 hours yields the best results.

With "BOTH" freeze-dryers, operators can input the set freeze-drying parameters into the equipment, enabling real-time switching to manual operation. Freeze-drying data can be monitored, and parameters adjusted at any time during the process. The system also automatically monitors, detects, and records relevant data, with features such as automatic alarm functions and defrost capabilities to ensure optimal freeze-drying results.

Control of Desorption Drying Time to About 8 Hours

After sublimation drying, capillary walls of the ginseng still contain moisture that needs to be removed. This moisture requires sufficient heat for desorption. In the desorption drying phase, the ginseng’s material temperature should be raised to a maximum of 50°C, and the chamber should maintain a high vacuum to create a pressure differential to aid the evaporation of water vapor. "BOTH" Freeze Drying recommends controlling the desorption drying time to about 8 hours.

Timely Post-Treatment of Ginseng

Post-treatment of ginseng is relatively simple. After drying, it should be immediately vacuum-sealed or nitrogen-purged. "BOTH" Freeze Drying reminds users that ginseng is highly hygroscopic after drying, so operators must prevent it from absorbing moisture and deteriorating. The laboratory environment should be kept dry.

Active ginseng processed with a freeze-dryer has better quality and appearance than ginseng dried by traditional methods such as red ginseng or sun-dried ginseng. This is because active ginseng is dehydrated at low temperatures, preserving its enzymes, making it easier to digest and absorb, and retaining its medicinal properties. Furthermore, it can be rehydrated to its fresh state by soaking in low-concentration alcohol or distilled water.

Finally, "BOTH" Freeze Drying reminds everyone that processing ginseng of different sizes and using different freeze-dryers will result in some variation in the freeze-drying curve. During the experiment, it is essential to remain flexible, analyze the specific situation, adjust freeze-drying parameters, improve drying speed, and ensure optimal freeze-drying results.

A good freeze-dryer provides stable temperature, vacuum, and condensation effects, ensuring uniform distribution of heat and mass during the freeze-drying process, thus improving drying efficiency and product quality. In addition, a quality freeze dryer can reduce energy consumption and costs in research experiments, guaranteeing the final product's appearance and quality. As a professional vacuum freeze-drying service provider, "BOTH" Freeze Drying specializes in providing high-performance freeze-dryer designs and customized vacuum freeze-drying solutions, precisely matching the needs of different freeze-drying materials. The professional team at "BOTH" Freeze Drying is dedicated to offering comprehensive and expert operational guidance to help each operator get up to speed quickly, improving research and production efficiency.

Post time: Dec-09-2024