Most high-pressure reactors consist of several key components, including a stirrer, reaction vessel, transmission system, safety devices, cooling systems, heating furnace, and more. Below is a brief introduction to the composition of each part.

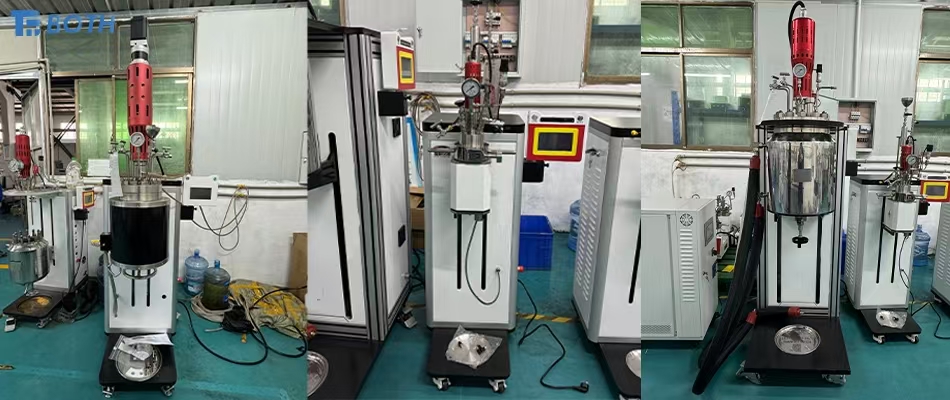

BOTH Instruments’ Custom Non-Standard Small Laboratory Reactors

Stirrers are generally divided into two types: mechanically driven stirrers powered by magnetic coupling devices and magnetic stirrers. The former uses a magnetic coupling device to drive the stirring blades at high speeds, ensuring uniform mixing of the reactants. It allows for interchangeable stirring blade structures tailored to different reactants, making it suitable for handling viscous materials. Common blade structures include axial flow blades, propeller blades, inclined blades, and anchor blades. The latter, the magnetic stirrer, relies on magnetic force to drive the reactants in the container. It comprises a driver and a magnetic stir bar. The stirring principle involves the driver generating a rotating magnetic field, causing the magnetic stir bar to rotate under the influence of magnetic forces, thus driving the reactants within the container.

The reaction vessel serves as the site where chemical reactions take place. Based on volume, reaction vessels can be categorized as small-scale high-pressure reactors, pilot-scale high-pressure reactors, and large-scale high-pressure reactors. The pressure resistance of a reaction vessel depends on its material and wall thickness. Vessel materials can be chosen based on the characteristics of the reactants, ranging from ordinary steel to corrosion-resistant, high-temperature alloys. Both Instruments offers a wide variety of reaction vessel materials to meet most market demands.

BOTH Instruments’ Liftable High-Pressure Reactors and Horizontal Reactors

Transmission system: Refers to the equipment that drives the inflow and outflow of materials and reaction products in the reactor, such as various types of pumps and flow meters.

Safety devices: Broadly, this includes pressure gauges installed on the reactor lid, rupture disk safety devices, gas-liquid phase valves, temperature sensors, and safety mechanisms like interlock alarms. Additionally, a cooling water jacket can be installed between the high-pressure reactor’s coupling and lid. When operating at high temperatures, cooling water should be circulated to prevent magnetic steel demagnetization caused by excessive temperatures, thereby enhancing safety.

Cooling systems: Include internal or external condenser coils, temperature circulation devices, and more.

Heating furnace: Small-volume high-pressure reactors typically use electric heating, with an external jacket housing the heating furnace. Other heating methods include jacketed thermal oil heating and jacketed circulating water heating.

If you are interested in our High Pressure Reactor or have any questions, please feel free to Contact us.

Post time: Jan-06-2025