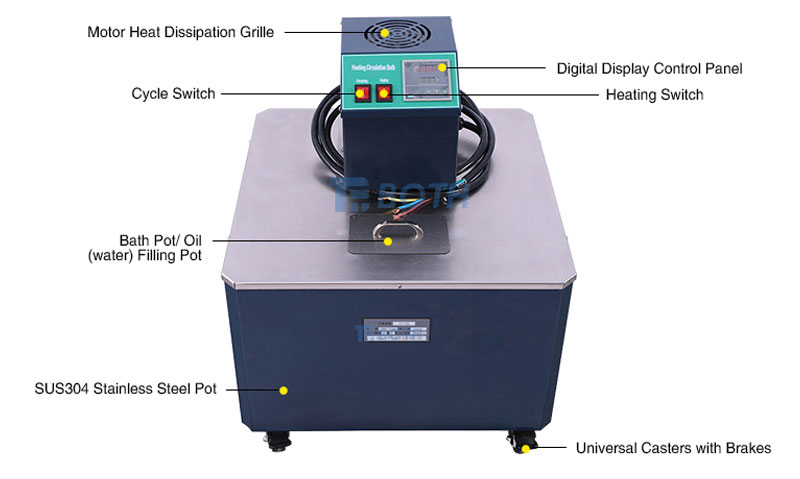

New High-temperature Heating Circulator GY Series

● The inner liner of the high-temperature circulating oil bath pot is made of sanitary SUS304 stainless steel plate material, and the shell is made of high-quality cold plate electrostatic spray plastic.

● The electric heater is placed in the center of the pot bottom, which has the advantages of fast heating, high thermal efficiency, low power consumption, safety and no leakage.

● The interlayer between the oil bath shell and the outer wall of the inner tank is filled with heat insulation cotton, which has excellent heat preservation effect.

● The circulating pump inside the high temperature circulating oil bath/tank exclusively adopts the efficient heat dissipation package design to ensure the instrument can work continuously and efficiently for a long time.

● Temperature control system through improvement, adding controllable silicon (3KW below) or solid state relay (3KW above) as the machine heating control core; The principle of silicon controlled is to regulate the voltage and temperature by the weak current signal of the instrument; The solid state relay relies on the micro-voltage signal of the instrument to operate the switching output, so as to realize the control of the output end of the heater.

● The temperature sensing part adopts K type armored platinum resistance, and the seal cartridge adopts copper tube coating process, which can conduct heat quickly; Platinum resistance sensor is a kind of high - end temperature measuring products, has the characteristics of small resistance and high precision.

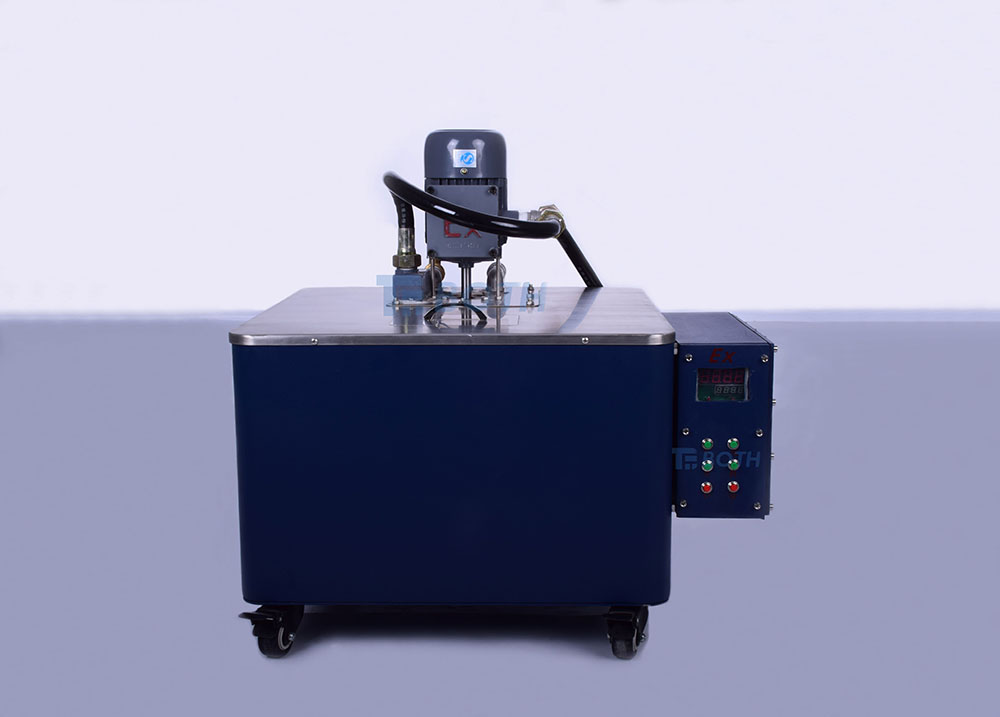

Optional Explosion-proof Motor, Explosion-proof Electric Equipment

|

Model |

GY-5 |

GY-10/20 |

GY-30/50 |

GY-80/100 |

|

Matching Double Layer Reactor |

1-5L |

10-20L |

30-50L |

80-100L |

|

Material |

304 Stainless steel |

|||

|

Volume(L) |

12 L |

28 L |

50 L |

71 L |

|

Pump Power(W) |

40W |

120W |

120W |

120W |

|

Heating Power(KW) |

2 KW |

3 KW |

5 KW |

8 KW |

|

Power Supply(V/Hz) |

220/50 |

220/50 |

220/50 |

380/50 |

|

Flow(L/min) |

5-10 |

|||

|

Lift(m) |

8-12 |

|||

|

In & Out of The Oil Nozzle |

1/2''/DN15 |

3/4''/DN20 |

||

|

In & Out of The Tubing |

Stainless Steel Bellows |

|||

|

The Temperature Control Mode |

Intelligent Temperature Control |

|||

|

Temperature Display Mode |

K-type Sensor Digital Display |

|||

|

Temperature Control Range of Bath Pot |

0-250℃ |

|||

|

Temperature Control Accuracy |

±1℃ |

|||

|

Tank Dimension(mm) |

∅250*240 |

390*280*255 |

430*430*270 |

490*440*330 |

|

Body Dimension(mm) |

305*305*440 |

500*400*315 |

500*500*315 |

550*500*350 |

|

Boundary Dimension(mm) |

435*305*630 |

630*400*630 |

630*500*630 |

680*500*665 |

|

Package Dimension(mm) |

590*460*460 |

730*500*830 |

730*600*830 |

780*600*865 |

|

Packed Weight(kg) |

16 |

33 |

36 |

40 |

|

Optional |

Optional Explosion-proof Motor, Explosion-proof Electric Equipment |

|||

|

* When ordering, please state the specifications of the inlet and outlet of the reactor |

||||