Hot Sale 1-5L Lab Filter Glass Reactor

● The reactor can be Swing Rotation (Horizontal Rotation) & Tilting Rotation(Vertical Rotation); lt is really convenient for user to replace the reactorbody, discharging and cleaning.

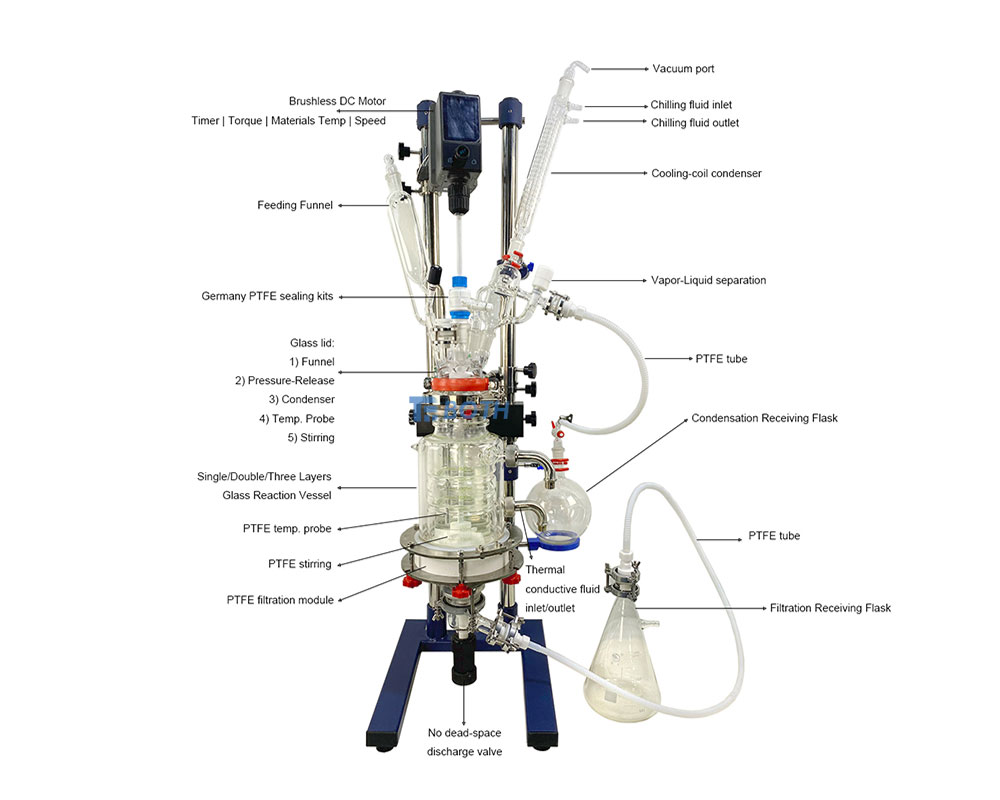

● The unique design of the vapor-liquid separator, not only can reflux into thereactor, but also can oollect into the receiving flask without anyaccumulated fluid.

● The full jacket design means that the jacket completely covers the reactor body, providing maximum heat transfer to the reaction process; The design of full jacket has no dead heat conduction space.

● The Ring Baffles inside of thermal layer improve the rapid thermaltransitions and uniform temperature distribution.

Integrated motor controller with a real-time display of the material temperature, torque and speed, as well as it has a auxiliary timing function.

The unique design of the vapor-liquid separator, not only can reflux into the reactor, but also can collect into the receiving flask without any accumulated fluid.

PTFE stirring seal goes deep inside the lid, it keeps the perfect stability without swing when shaking in high speed stirring.

Interface adopt the international technical standard, size standardization, serialization, long-length ground glass joints joints sealing. All belong to the same type of specification interface, can be interchangeable arbitrarily and easily.

The Ring Baffles inside of thermal layer improve the rapid thermal transitions and uniform temperature distribution. Experiments have proved that the heating time of the reactor with Ring Baffles is shortened by 60% and the cooling time by 52%.

Full-jacket design for high thermal performance.

| Model* |

GDF-300S |

GDF-500S |

GDF-1000S |

GDF-2000S |

GDF-3000S |

GDF-5000S |

| ①Optional |

GDF-300ST |

GDF-500ST |

GDF-1000ST |

GDF-2000ST |

/ |

/ |

| Glass Material |

High Borosilicate Glass 3.3 |

|||||

| Frame Structure |

"H" Type Structure Frame |

|||||

| Wetted Parts |

Glass and PTFE without Any Metal Pollution |

|||||

| Reactor Capacity |

300ml |

500ml |

1000ml |

2000ml |

3000ml |

5000ml |

| Jacket Type |

Full Jacket Design with Ring Baffles inside of Thermal Jacket |

|||||

| Thermal Jacket Volume |

90ml |

150ml |

300ml |

600ml |

900ml |

1500ml |

| Filtration Area |

95 cm² |

95 cm² |

95 cm² |

113 cm² |

176 cm² |

176 cm² |

| Filtration Micron |

Micron: 0.2μm to 200μm |

|||||

| Stirring Motor* |

DC Brushless Motor With "Get Through" Hole for Stirring Rod |

|||||

|

50W |

50W |

50W |

100W |

100W |

150W |

|

|

50 ~ 2200 RPM |

||||||

| Integrated Control & Display |

Current Stirring Speed/Set Stirring Speed/Timer/Materials Temperature/Torque/ RS232 Data Communication Port |

|||||

| ②Optional |

AC Motor with Gear Reducer |

|||||

|

90W |

90W |

90W |

90W |

90W |

120W |

|

|

50 ~ 600 RPM |

||||||

|

Ex DIIBT4 Explosion Proof Motor |

||||||

|

90W |

90W |

90W |

90W |

90W |

180W |

|

|

50 ~ 600 RPM |

||||||

| Integrated Control & Display |

Current Stirring Speed/Materials Temperature |

|||||

| Stirring Impeller |

PTFE Anchor Type or PTFE Pitched Paddle Type or PTFE Frame Type |

|||||

| Sealing for Agitator |

PTFE+Mechanical Double Sealing Max Vacuum -0.098MPa |

|||||

| Glass Lid |

#150 |

|||||

| 5 Openings: 1) Dropping Feeding Funnel: 24/40 2) Pressure Release/Feeding Port/Inert Gas Inlet: 24/40 3) Temperature Probe: 15# 4) Condenser: 24/40 5) Stirring: 50# | ||||||

| Constant Pressure Drop Feeding Funnel* |

Single Layer Dropping Feeding Funnel with PTFE Needle Valve and Equalizing Arm |

|||||

|

100ml |

100ml |

100ml |

200ml |

200ml |

500ml |

|

| ③Optional |

1) Jacketed Glass Feeding Funnel 2) Powder Feeding Funnel 3) Peristaltic Pump or Other Metering Pumps Feeding |

|||||

| Temperature Probe |

PT100 with PTFE Layer +/-1°C |

|||||

| Condenser* |

Double Cooling-Coil Condenser |

|||||

| ④Optional |

Vapor-Liquid Separator |

|||||

| Operating Temperature |

-90°C to +230°C |

|||||

| ΔT - Thermal Shock Resistance |

90°C (Double Wall), 60 °C(Triple Wall) |

|||||

| Operating Pressure |

Full Vacuum to Atmospheric Pressure |

|||||

| Operating Jacket Pressure |

Up to +0.5 bar (0.05 MPa) |

|||||

| Power Supply |

100V ~ 240V, 50Hz/60Hz or Customized |

|||||

| ①GDF-300/5000S, Reactor can be Swing Rotaiotn (Horizontal Rotation); GDF-300/2000ST, Reactor can be Swing Rotaiotn (Horizontal Rotation) & Tilting Rotation (Vertical Rotation). ②Stirring Motor, AC Motor or Explosion Proof Motor is an option for upgrading. ③Constant Pressure Drop Feeding Funnel can be replaced with 1) Jacketed Glass Feeding Funnel 2) Powder Feeding Funnel 3) Peristaltic Pump or Other Metering Pumps Feeding ④Condenser Can Be Equipped withVapor-Liquid Separator, Not Only Can Reflux into Reactor, But Also Can Collect into Receiving Flask without Any Accumulated Fluid. |

||||||